The Chittagong fires in the depot have caught worldwide attention. It has so far killed 49 people, and many others are injured. This sort of debacle is frequently seen in Bangladesh over three to four years and cannot be indistinguishable from any other mishap. The debacle and misery of this kind have been taking place where mismanagement looms large, and the accidental occurrence of disaster cannot be the sole reason for concern. The perspective view is about Causes And Explanations of Chittagong Depot Fire.

Have intricately linked events become the cause for Endangerment?

The Chittagong fires give us an idea of how the fires were generated through an unlikely event and how the link between ill-fated factors could usher in the need for further investigation. The origins of the fire and how it started can be directed to various sources, but most importantly, it could be that the inevitability was high likeliness, and the depot held few barrels of chemicals which could have been fire hazardous and of nature of health risk. Unfortunately, the origins of the fire which sparked the explosion are still unknown.

Possible causes may be a bad electrical system, sparks, and short circuits, along with the presence of smoke and other hazardous fire material. Few of the containers had HCL in them, which, when exploded, could be a hazard for people present. We all know what Acidic materials with a low PH value can do in contact with skin, and the erosion can cause skin lesions and burns on the heavy side.

Again discussions can be set up, but the exact origins of the fire are still unknown, and the causes cannot be set up to extrapolate its effects.

The structural analysis is one such affect that boils down to the stability of the structure itself. The depot in question was under a roof shed that was 650 meters long. Its sudden collapse represents the glitches in the design of the whole depot. With repeating, the shed was made of steel or galvanized aluminum. The entire collapse was due to breaking the tall outside structure housing the depots.

As we know, the metals begin to deform under intense heat, and under certain loads in the heat, somewhere down the middle or places of high-pressure constraints occur. This is precisely why the shed collapsed because, under extreme heat, the structure was viable to breaking and is the only reason for the collapse of the shed upon the depot. Also, we need to know the steel structure prevalently made to handle high temperatures broke down in the first place.

According to the general design of RCC buildings, concrete-based exteriors and housing are a requirement of high tensile strength and ductility, but as there is little evidence as to why the fire started from which place, that’s why the question becomes unclear as to the reason for it beginning in the first place. The depot housing can be made of a combination of beams and slabs, which should resist vertical and horizontal loads. In addition, the structure should have balanced trusses that keep stability as it is and help stability become the number one concern.

For vertical framing systems, the columns and foundations of depots there are vertical loads and vertical framing systems. Since the deopts are housed one upon the other and cover a large area, in this case, for the BN Depot of 23 acres, the loads are a prerequisite for stability. The floor slabs are 150 mm thick with a span of 7m. The slabs provide the base for supporting the entire depot. Any measurements outside of this should be the sole reason for the structural breakdown.

The limit state design(LSF) or the Load and resistance factor design should have been enough to avoid structural collapse. The ultimate limit state(ULS) and the serviceability limit state(SLS) can form the two factors for load-bearing capacity in the vertical state. The ultimate state is the factor that depends on the deformations and variations in tensile forces under pre-agreed values, but the ultimate limit state is the value of the bending, shear, tensile and compressive stress under preassigned values for a section of the vertical column.

The magnified loads are less than reduced resistances when considering the load-bearing elements. Now the SLS state is determined by computational checks. This involves stress behavior, dynamic loading, flexibility, and deformations. This is done to test imposed deformations, vibrations, and the effect of a temperature gradient. According to preassigned values, everything is done to have a sense of human comfort and service level.

The load factors are quite different than is expected:

The quality of material and the quality of construction are two interlinked factors. There is a preassigned probability of failure where a value of unity or less is for resistance or loads and a value greater than for loads. Sometimes the values are lower than unity due to the combination of loads.

The corrosion resistance of the Chittagong depot’s materials was an unlikely factor. Normal metallurgy tells us that reinforced steel and galvanized aluminum can withstand high temperatures. Any inconveniences in make up-basically the conversion between pearlite, martensite, and bainite and the combination of throws some interesting questions into the mix. If there is a faulty mechanism with which the depot structure was built, then it means that the internal stresses developed could have a bearing on structural rigidity. Structures components include connecting rod, truss, beam, column, cavity, arch, surface structure, and frame are all part of the design process.

The loads can be of two types: the structural members and various components of the structural members. The mechanics of the materials approach, which involves dynamic response, stability, and non-linear behavior, could become the factors concerning materials, elastic element, and finite elements approach. Instead, however, the factors are equilibrium, constitutive, and compatibility. This comes from the sense that pre-existing building codes(NFPA and BNBC) can be applied to extrapolate a fine system of conditional behaviors of structures under immense heat and on the brink of collapse.

Importance should be given to structural deformities and withstanding extreme heat and pressure capacity. There are intersecting points or nodes at various points in a certain structure. Any external force on this node can cause imbalances according to the design of this structure and in turn, have a greater force than the force in design consideration. The most important factors of consideration are the plasticity of the materials and how the chemicals and fire act in tandem in this case of ctg depot and cause structural breakdown and fire spread.

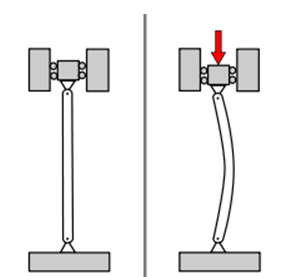

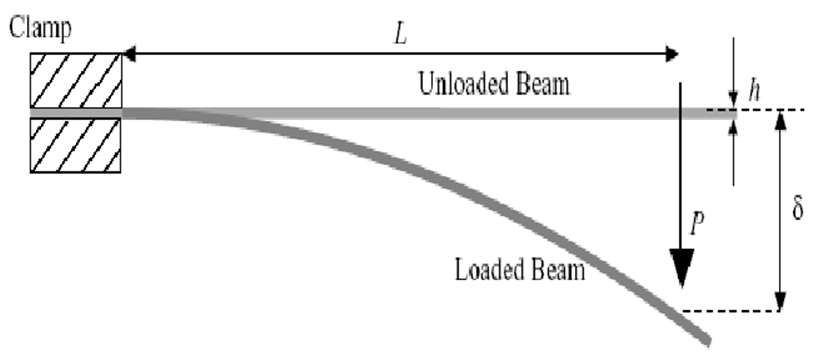

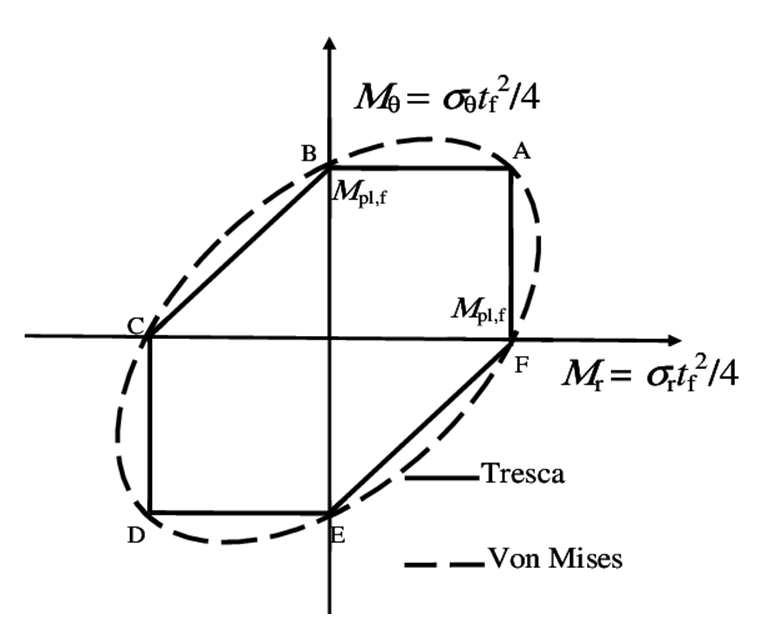

Let’s look at the Tresco and von mises diagram for further explanation. The upper load is defined by the moment of load not being equal to or greater than the yield load; then, the load is called the lower bound on the collapsed load. Secondly, if the moment of the load exceeds the yield load and work is done for displacement, then the load is called the upper bound load on the collapsed load. Another factor that keeps gathering pace is the deflection of the cantilever beam and the buckling of rods under pressure. Both hold some importance in this case and can be the factors affecting the collapse of the depot structure along with the destruction of materials inside through raging fires.

Here are a few examples of deflection and buckling through a few images:

1. The first image represents how vertical stresses can cause deformations, also known as buckling

2. The second picture is the instability of a beam and how it bends under loads and how it breaks

3. The third part is the Tresca van mises diagram and how it affects the loads under consideration

This can together act as a part of the overall structural balance. The Ctg depot had problems somewhere down the line considering this theory, and this made the case today.

The more relevant problem in the cause of the depot fire may have been containment. In the depot, there were chemically active materials such as HCL and gaseous hydrogen peroxide. Four containers in recent news in the place were found to contain hydrogen peroxide, the cause of the flames. Hydrogen peroxide can be severely explosive when flammable and uses dry fire-based refrigerants to cool off the fire. However, it is a very powerful oxidizing agent and should be why the fire got out of control. Hydrogen peroxide is non-flammable and decomposes in the presence of light. Hydrogen peroxide can come in contact with water from chlorine, which should be used properly.

The location of the chemical-laden containers was difficult to find, but the rescue job did help. Water used by the Firebrigade to vanquish the flames is mixed with chemicals and released into the near Kashem Jute Mill. Contaminated water poses a severe health risk to many, and a proper method of extinguishing should be used to cut off the flame. The fire has caused much damage and taken many lives, including ten firefighters. The loss is undoubtedly a big impact of mismanagement along with the disability to foresight that sort of information. Fire can never be the cause of danger, and mismanagement is the cause of real danger. The air quality has also become a cause of suffering as pungent chemicals from the fire are up into the neighboring area. The army blocked gateways into the bay of Bengal as harmful chemicals would seep through the flow stream.

At last, the fire disaster at the BM depot indicated what Bangladesh lacks. The disability to foster good working conditions should pave the way for immediate measures for control. The fire depot and the lives it consumes are not the first in Bangladesh; in 2019, a hundred died in a cramped space of apartments and warehouses, and many others died in the year 2021 at a food and beverage factory outside Dhaka. These cases are intricately linked, and authorities are learning and doing little to overcome the massive blows these types of events will have on Bangladesh and people who want to do business with Bangladesh. This can not be the step towards unilateral unification, and all that needs to be done is done through a series of events.

Engr. Samin Shadman Zahir

Contributor, The InCAP

To read more articles from Perspective Views, Please Click Here!